Modern Automotive Workshop Efficiency: Elevating Service Standards

In today's fast-paced automotive industry, efficiency and productivity are paramount to success. The choice between a car scissor lift and traditional floor jacks represents a crucial decision that can significantly impact a workshop's operational effectiveness. As vehicle maintenance becomes increasingly complex, selecting the right lifting equipment has never been more important for automotive professionals seeking to optimize their workflow and enhance service delivery.

The automotive repair landscape has evolved dramatically over the past decade, with technological advancements revolutionizing how vehicles are maintained and repaired. This evolution demands equipment that can meet modern challenges while ensuring technician safety and workflow efficiency. Understanding the distinct advantages and limitations of both car scissor lifts and traditional floor jacks is essential for making an informed decision that aligns with your workshop's specific needs.

Equipment Investment and Long-term Value

Initial Cost Considerations

When evaluating the financial aspects of workshop equipment, the initial investment in a car scissor lift typically exceeds that of traditional floor jacks. However, this higher upfront cost must be viewed through the lens of long-term value. A quality car scissor lift represents a substantial investment in infrastructure that can serve your workshop for many years, potentially offering better returns through increased efficiency and service capacity.

Traditional floor jacks, while more affordable initially, may require regular replacement and maintenance, especially in high-volume operations. The cumulative cost of replacing worn-out floor jacks, combined with potential workplace injuries and slower service times, can ultimately exceed the initial investment of a car scissor lift system.

Return on Investment Analysis

A comprehensive ROI analysis reveals that car scissor lifts often pay for themselves through improved workflow efficiency and increased service capacity. Workshops equipped with scissor lifts typically report handling more vehicles per day, with technicians spending less time on vehicle positioning and more time on actual repair work. This increased throughput directly translates to higher revenue potential and better resource utilization.

The durability and reliability of modern car scissor lifts also contribute to their long-term value proposition. With proper maintenance, these systems can operate dependably for decades, making them a sound investment for forward-thinking automotive businesses.

Operational Efficiency and Workflow Impact

Time Management Benefits

The impact of a car scissor lift on workshop efficiency cannot be overstated. Technicians can raise vehicles to working height in seconds, compared to the multiple steps required with traditional floor jacks. This time savings compounds throughout the day, allowing for more efficient service delivery and increased customer satisfaction. The stable platform provided by scissor lifts also enables technicians to work more confidently and efficiently, reducing the time spent repositioning or adjusting equipment.

Traditional floor jacks, while versatile, often require additional time for proper positioning, safety stand placement, and height adjustments. These incremental delays can significantly impact daily productivity, especially in high-volume service environments where minutes matter.

Workspace Optimization

Car scissor lifts contribute to better workspace organization by providing a clean, uncluttered service area. The integrated design means less equipment scattered around the shop floor, reducing trip hazards and improving overall safety. This organized environment allows for more efficient tool access and better workspace utilization.

Workshops utilizing traditional floor jacks often struggle with space management, as jack stands, wheel chocks, and other supporting equipment must be stored and managed. This can lead to cluttered work areas and reduced efficiency in high-traffic service bays.

Safety and Ergonomic Considerations

Worker Health and Comfort

The ergonomic advantages of car scissor lifts significantly reduce physical strain on technicians. The ability to raise vehicles to optimal working height helps prevent back injuries and repetitive strain issues commonly associated with traditional floor jack usage. Technicians can maintain better posture throughout their workday, potentially reducing fatigue and improving overall job satisfaction.

Working with floor jacks often requires technicians to assume awkward positions and make frequent adjustments, increasing the risk of musculoskeletal injuries. The physical demands of manipulating heavy floor jacks and safety stands can lead to worker fatigue and reduced productivity over time.

Workplace Safety Standards

Car scissor lifts incorporate multiple safety features, including automatic locking mechanisms and fail-safe systems that provide peace of mind for both technicians and management. These safety features comply with modern workplace safety regulations and help reduce the risk of accidents or equipment failure.

While traditional floor jacks can be used safely when proper procedures are followed, they inherently carry more risk factors. The potential for jack failure, improper stand placement, or vehicle stability issues presents ongoing safety concerns that must be actively managed.

Versatility and Application Range

Vehicle Compatibility

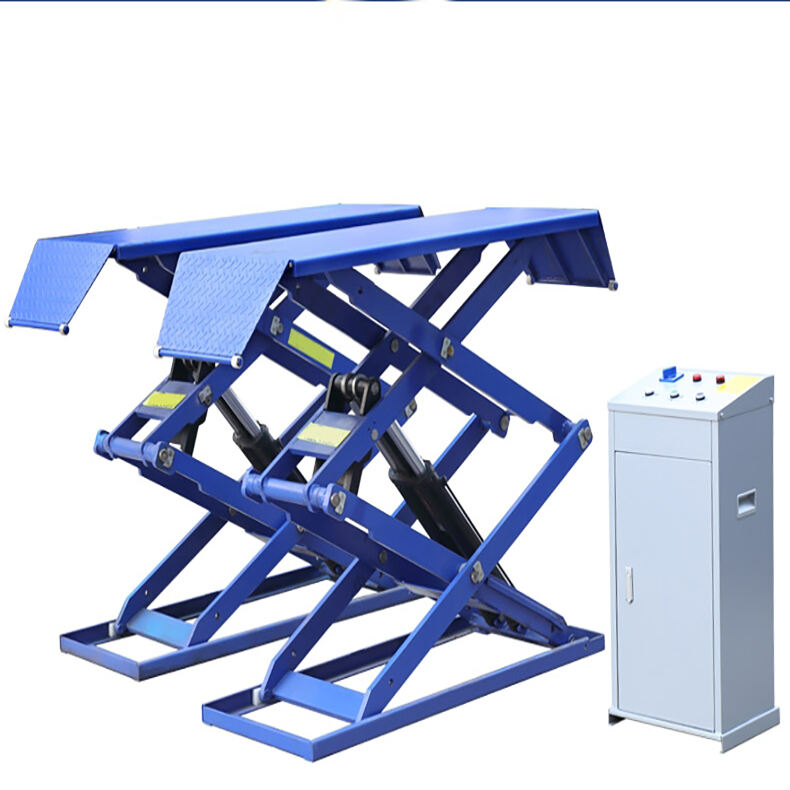

Modern car scissor lifts are designed to accommodate a wide range of vehicles, from compact cars to light commercial vehicles. Their adjustable lifting points and stable platform make them suitable for various service operations, from routine maintenance to complex repairs. This versatility ensures that workshops can serve a diverse customer base efficiently.

The adaptability of scissor lifts to different vehicle types and service requirements makes them an invaluable tool for workshops looking to expand their service capabilities and attract new business opportunities.

Service Flexibility

The stable platform provided by car scissor lifts allows technicians to perform multiple services simultaneously, improving workflow efficiency and reducing vehicle turnaround time. From oil changes to brake services, the consistent working height and stability enable more confident and precise work execution.

Traditional floor jacks, while portable, often limit the types of services that can be performed simultaneously and may require frequent repositioning for different service tasks. This limitation can impact workshop productivity and service delivery times.

Frequently Asked Questions

How long does a car scissor lift typically last with proper maintenance?

A well-maintained car scissor lift can provide reliable service for 15-20 years or more. Regular maintenance, including lubrication, safety checks, and professional inspections, is essential for maximizing equipment longevity and ensuring safe operation throughout its service life.

What are the power requirements for installing a car scissor lift?

Most car scissor lifts require 220-240V power supply with appropriate amperage capacity. It's important to consult with a qualified electrician to ensure your facility meets the specific power requirements of your chosen lift system. Some models may also offer pneumatic or hydraulic power options.

Can a car scissor lift be installed on any workshop floor?

Installation requirements typically include a level concrete floor with sufficient thickness and strength to support the lift and vehicle load. A professional site assessment is recommended to evaluate floor conditions, ensuring they meet manufacturer specifications for safe installation and operation.