الدليل الأساسي لاختيار الرافعة المحمولة المثالية رافعة السيارة

سواء كنت ميكانيكيًا شغوفًا بالعمل اليدوي أو تدير ورشة متخصصة في الصيانة، فإن الاستثمار في رافعة سيارات محمولة يمكن أن يُحدث تحولًا كبيرًا في قدرتك على صيانة المركبات. رافعة السيارة توفر هذه الأدوات المتعددة الاستخدامات التوازن المثالي بين الوظائف والراحة، مما يسمح لك بالعمل على المركبات مع رفعها بمستوى احترافي، مع الحفاظ في الوقت نفسه على المرونة لإعادة استخدام مساحة العمل عند الحاجة. سيُطلعك هذا الدليل الشامل على كل ما تحتاج لمعرفته لاختيار الرافعة المحمولة المثالية وفقًا لمتطلباتك الخاصة.

التعرف على أنواع الرافعات المحمولة وتطبيقاتها

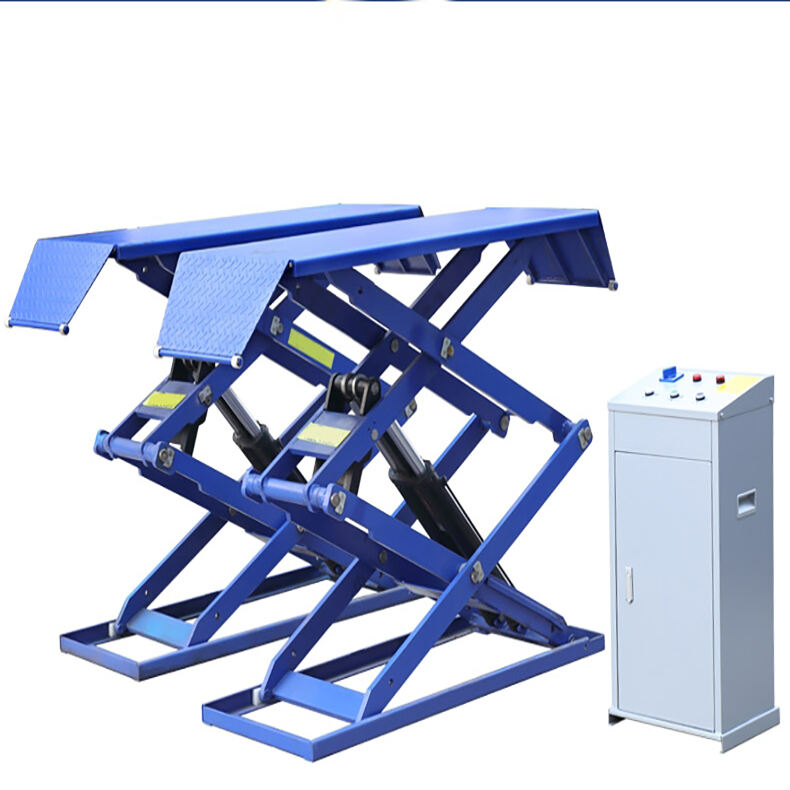

الرافعات المقصية وميزاتها

تمثل رافعات المقص إحدى أكثر تصاميم رافعات السيارات المحمولة شيوعًا، وتحتوي على آلية دعم متقاطعة ترفع المركبات وتُخفضها بسلاسة. تتميز هذه الرافعات بتصميمها المدمج عند طيّها، مما يجعلها مثالية للورش ذات المساحة المحدودة. يمكن للرافعات الحديثة من نوع المقص عادةً تحمل أوزانًا تتراوح بين 3000 و6000 رطلاً، مما يوفر سعة كافية لمعظم المركبات الخاصة والشاحنات الخفيفة.

تتمثل الميزة الرئيسية لرافعات المقص في استقرارها الاستثنائي والمساحة الصغيرة التي تحتلها. وعند وضعها في الموضع الصحيح، فإنها توزع الوزن بالتساوي عبر عدة نقاط، مما يضمن رفعًا آمنًا ومستقرًا. كما يتيح تصميمها تخزينًا سهلاً، حيث يمكن نقل معظم الموديلات بعيدًا على عجلات أو إدخالها بجانب الحائط عند عدم الاستخدام.

حلول محمولة ثنائية الدعامات وأربعية الدعامات

توفر رافعات الركائز الثنائية المتنقلة تنوعًا استثنائيًا وتشتهر بشكل خاص بين الميكانيكيين المحترفين. توفر هذه الأنظمة وصولاً ممتازًا إلى المركبة، مما يتيح الوصول غير المعوق إلى العجلات ومكونات الفرامل ومناطق الهيكل السفلي. وبينما كانت تُربط تقليديًا بالتثبيتات الدائمة، فإن الإصدارات الحديثة المتنقلة تجمع بين الحركة والقدرات الرافعة القوية.

على الرغم من حجمها الأكبر، توفر رافعات الركائز الرباعية المتنقلة ثباتًا وسعة تحمل وزن أفضل. تتفوق هذه الأنظمة في حلول التخزين طويلة الأجل وهي مثالية للمحلات التي تحتاج إلى الاستفادة القصوى من مساحة الخدمة. وتتميز العديد من الموديلات بمسارات عجلات مدمجة، مما يجعلها مناسبة تمامًا لأعمال المحاذاة وتحديد مواقع المركبة بدقة.

الميزات الحرجة للسلامة ومتطلبات الشهادات

الآليات الأمنية الأساسية

عند تقييم رافعات السيارات المحمولة، يجب أن تكون ميزات السلامة هي اعتبارك الأساسي. ابحث عن الموديلات المزودة بمواضع قفل متعددة، مما يسمح بالتوقف الآمن عند مختلف الارتفاعات. تعد أقفال السلامة التلقائية، وأزرار الإيقاف الطارئ، وأنظمة الحماية من الحمل الزائد ميزات لا يمكن الاستغناء عنها لضمان سلامة المشغل والسيارة على حد سواء.

يجب أن تتضمن رافعات السيارات المحمولة الحديثة أيضًا صمامات أمان هيدروليكية أو فيوزات السرعة التي تمنع الهبوط المفاجئ في حالة فشل النظام الهيدروليكي. هذه التدابير الوقائية، إلى جانب مؤشرات توزيع الوزن المناسبة وبنيتها القاعدية المستقرة، تُشكل نظام سلامة شاملاً.

معايير الشهادات والامتثال

أي رافعة سيارات محمولة تستحق النظر يجب أن تفي بمعايير السلامة الصناعية أو تتجاوزها. ابحث عن شهادة منظمات معترف بها مثل معهد رفع المركبات (ALI) أو العلامة CE الخاصة بالمعايير الأوروبية. تضمن هذه الشهادات أن الرافعة خضعت لاختبارات صارمة وتفي بمتطلبات السلامة الصارمة.

يجب تحديد نقاط الفحص الدورية وجداول الصيانة بوضوح في وثائق الشركة المصنعة. تساعد هذه المعلومات في الحفاظ على ميزات السلامة للرافعة وضمان موثوقيتها على المدى الطويل.

سعة الوزن ومتطلبات المساحة

تحديد التصنيفات المناسبة للوزن

يتطلب اختيار سعة الوزن المناسبة النظر بعناية في احتياجاتك النموذجية لصيانة المركبات. يجب دائمًا اختيار رافعة سيارات محمولة ذات تصنيف يفوق على الأقل 25٪ من أقصى حمولة متوقعة. يُراعى هذا الهامش الأمني لتوزيع غير متساوٍ للوزن والأحمال الديناميكية أثناء حركة المركبة.

ضع في اعتبارك ليس فقط وزن المركبات القياسية، بل أيضًا أي معدات متخصصة أو تعديلات قد تؤثر على الحمولة الكلية. يمكن للسيارات الرياضية المعدلة بشكل كبير أو المركبات الفاخرة ذات المكونات المعززة أن تؤثر تأثيرًا كبيرًا على متطلبات الوزن.

تخطيط المساحة وحلول التخزين

يتطلب تنفيذ رافعة السيارات المحمولة بنجاح تخطيطًا دقيقًا للمساحة. قم بقياس مساحة العمل المتاحة بعناية، مع أخذ بُعد النظر ليس فقط إلى مساحة قاعدة الرافعة نفسها، بل أيضًا إلى المنطقة المحيطة الضرورية للتشغيل الآمن. تذكّر أن تأخذ في الاعتبار زوايا اقتراب المركبة والمساحة اللازمة لفتح الأبواب واستخدام الأدوات.

يجب التخطيط لحلول التخزين مسبقًا، خاصةً في المرائب المنزلية حيث تكون المساحة محدودة. يمكن تفكيك العديد من رافعات السيارات المحمولة أو طيّها لتسهيل التخزين في مساحة صغيرة، ولكن يجب التأكد من توفر مساحة كافية وظروف تخزين مناسبة للحفاظ على عمر المعدات الطويل.

متطلبات الكهرباء واعتبارات التركيب

الأنظمة الكهربائية والهيدروليكية

من الضروري فهم متطلبات الطاقة لتشغيل رافعة السيارة المحمولة بشكل صحيح. تعمل معظم الموديلات المنزلية على تيار كهربائي قياسي بجهد 110 فولت، في حين قد تتطلب الرافعات التجارية تغذية بجهد 220 فولت. يجب التأكد من أن نظامك الكهربائي قادر على تلبية احتياجات الرافعة من حيث استهلاك الطاقة، وينبغي النظر في تركيب دارة كهربائية مخصصة إذا لزم الأمر.

يجب تقييم الأنظمة الهيدروليكية من حيث سعة الزيت وجودة المضخة ومتطلبات الصيانة. ابحث عن الأنظمة التي تحتوي على دوائر هيدروليكية مغلقة لتقليل احتياجات الصيانة ومنع التلوث.

مواصفات الأرضية والتركيب

حتى الرافعات المحمولة تتطلب ظروف أرضية مناسبة لتشغيلها بأمان. فسماكة الخرسانة وقوتها الانضغاطية ومستوى السطح المستوي تلعب جميعها أدوارًا حاسمة في استقرار الرافعة. يحدد معظم المصنّعين الحد الأدنى لمتطلبات الخرسانة - وعادةً ما يكون ذلك 4 بوصات سماكة وقوة انضغاط 3,000 رطل لكل بوصة مربعة (PSI) للتطبيقات المنزلية.

اختر خدمات التركيب الاحترافية، خاصةً للأنظمة المحمولة الأكبر حجمًا. وعلى الرغم من أن العديد من الوحدات مصممة لتُركب ذاتيًا، فإن التركيب الصحيح يضمن أداءً أمثل وقد يؤثر على تغطية الضمان.

الأسئلة الشائعة

كم يستغرق عمر رافعة السيارة المحمولة عادةً؟

مع الصيانة المناسبة والتفتيش المنتظم، يمكن لرافعة سيارة محمولة عالية الجودة أن تدوم من 10 إلى 15 عامًا أو أكثر. ويعتمد العمر الفعلي على معدل الاستخدام وممارسات الصيانة والظروف البيئية. قد تحتاج الرافعات من الطراز المهني المستخدمة في الأماكن التجارية إلى الاستبدال قبل ذلك بسبب معدلات الاستخدام العالية.

هل يمكن استخدام الرافعات المحمولة للسيارات في الهواء الطلق؟

رغم أن بعض الرافعات المحمولة مصممة للاستخدام الخارجي أحيانًا، فإنه يُوصى عمومًا بتشغيلها وتخزينها داخليًا. إذ يمكن للتعرض للعوامل الجوية أن يسرّع التآكل ويُضعف ميزات السلامة. وإذا كان الاستخدام الخارجي ضروريًا، فتأكد من حماية الرافعة بشكل مناسب وتخزينها داخليًا عند عدم الاستخدام.

ما نوع الصيانة التي تتطلبها رافعة السيارة المحمولة؟

تشمل الصيانة الدورية التحقق من مستويات السوائل الهيدروليكية، وتزييت الأجزاء المتحركة، وفحص آليات السلامة، وشَد أي براغي أو وصلات فضفاضة. يُوصي معظم المصنّعين بإجراء فحوصات بصرية شهرية وفحوصات صيانة شاملة سنويًا. احتفظ بسجلات صيانة مفصلة لضمان الامتثال للضمان والأداء الأمثل.