Essential Equipment for Modern Auto Service Operations

The automotive service industry continues to evolve with technological advancements, and having the right equipment is crucial for any successful operation. A car tire changer represents one of the most fundamental yet critical pieces of equipment in any automotive workshop. With various models and specifications available in the market, selecting the optimal car tire changer requires careful consideration of multiple factors to ensure it meets your specific needs while delivering value for your investment.

Understanding Tire Changer Classifications

Manual vs. Automatic Tire Changers

Manual car tire changers require more physical effort and expertise from the operator but generally come at a lower price point. These machines are suitable for smaller shops with lower volume requirements or as backup units. The operator must control all aspects of the tire changing process, from breaking the bead to mounting and dismounting the tire.

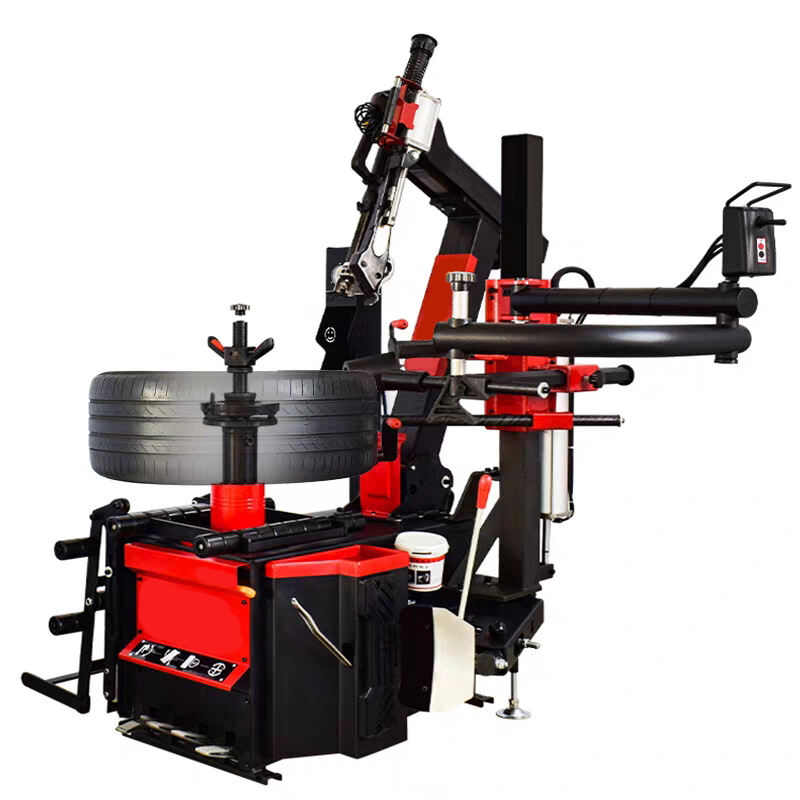

Automatic tire changers, while requiring a higher initial investment, offer enhanced efficiency and reduced physical strain on operators. These machines feature powered assist arms, automatic bead breakers, and pneumatic clamping systems that significantly speed up the tire changing process while minimizing the risk of damage to expensive wheels.

Swing Arm vs. Tilt Back Designs

Swing arm car tire changers utilize a traditional design where the mounting head moves horizontally on a swing arm. This configuration works well for standard passenger vehicle tires but may present challenges with larger or run-flat tires. The simpler mechanism typically means lower maintenance requirements and costs.

Tilt back models feature a mounting head that tilts backward, providing better access to the wheel and making it easier to work with low-profile tires and run-flats. These machines often incorporate additional helper arms and pressing tools to manage difficult tire and wheel combinations safely.

Key Features to Consider

Clamping System Capabilities

The clamping system serves as the foundation of any car tire changer, securing the wheel during the changing process. External clamping systems work well for most standard wheels but may require careful adjustment to prevent damage to expensive alloy wheels. Internal clamping mechanisms often provide better protection for custom wheels and more secure holding power for challenging applications.

Modern car tire changers may feature adjustable clamping pressure and protective jaw covers to accommodate different wheel types. The clamping range should match your expected workload, typically ranging from 10 to 26 inches for most passenger vehicle applications.

Bead Breaking Technology

Traditional shovel-type bead breakers work effectively on standard tires but may struggle with run-flat or low-profile tires. Advanced car tire changers incorporate roller-type or dynamic bead breaking systems that apply more controlled force, reducing the risk of wheel damage while improving efficiency.

Some premium models feature simultaneous dual bead breaking capability, significantly reducing the time required to break both beads. This feature becomes particularly valuable in high-volume shops where time efficiency directly impacts profitability.

Performance and Productivity Features

Helper Arms and Assist Devices

Modern car tire changers often come equipped with helper arms that provide additional support during difficult mounting and dismounting operations. These pneumatic assists can make the difference between struggling with tough combinations and completing jobs efficiently. Premium models may include multiple helper arms, pressure rollers, and specialized tools for run-flat tires.

The positioning and flexibility of these assist devices significantly impact operator comfort and efficiency. Look for systems that offer smooth operation and quick adjustability to accommodate different wheel sizes and tire types.

Speed and Power Specifications

The turntable motor's power and speed characteristics directly affect productivity. Two-speed motors offer flexibility for different applications, while variable speed control provides precise operation for demanding situations. Consider the electrical requirements and ensure your facility can support the machine's power needs.

Pneumatic systems should deliver consistent performance with standard shop air supplies, typically requiring 110-140 PSI for optimal operation. Verify that your air supply system can maintain adequate pressure during peak usage periods.

Space and Installation Requirements

Physical Dimensions and Layout

Before selecting a car tire changer, carefully evaluate your available space. Consider not only the machine's footprint but also the working area needed around it for efficient operation. Remember to account for storage of accessories, tools, and the space required to maneuver wheels and tires.

The machine's height may also be a consideration, especially in facilities with low ceilings or overhead obstacles. Some models offer compact designs specifically for shops with space constraints while maintaining full functionality.

Utility Requirements

Beyond physical space, consider the machine's utility requirements. Ensure your electrical system can handle the power demands and that adequate compressed air supply is available. Some advanced car tire changers may require dedicated circuits or three-phase power, which could impact installation costs.

Plan for proper lighting and ventilation in the tire changing area to support efficient operation and maintain a safe working environment. Consider the location of electrical outlets and air supply points when planning the machine's placement.

Frequently Asked Questions

What is the average lifespan of a car tire changer?

A quality car tire changer, when properly maintained, typically lasts 8-12 years in a professional shop environment. Regular maintenance, proper operation, and timely repairs can extend this lifespan significantly. The actual duration depends on usage volume, types of tires serviced, and maintenance practices.

How much training is required for operators?

Basic training for standard car tire changers usually takes 2-3 days for operators to become proficient. However, advanced machines with multiple features may require additional training time. Many manufacturers offer comprehensive training programs and ongoing support to ensure proper operation and maintenance.

Should I choose a new or used tire changer?

While used car tire changers may offer initial cost savings, new machines provide warranty coverage, current technology, and manufacturer support. New equipment typically offers better efficiency, reduced maintenance requirements, and the ability to handle modern wheel and tire combinations more effectively.